TrabTech announces seed investment for serialization of CE-certified 3D printed implants and research fund of 1.3 million euros for development of 3D printable smart biomaterials

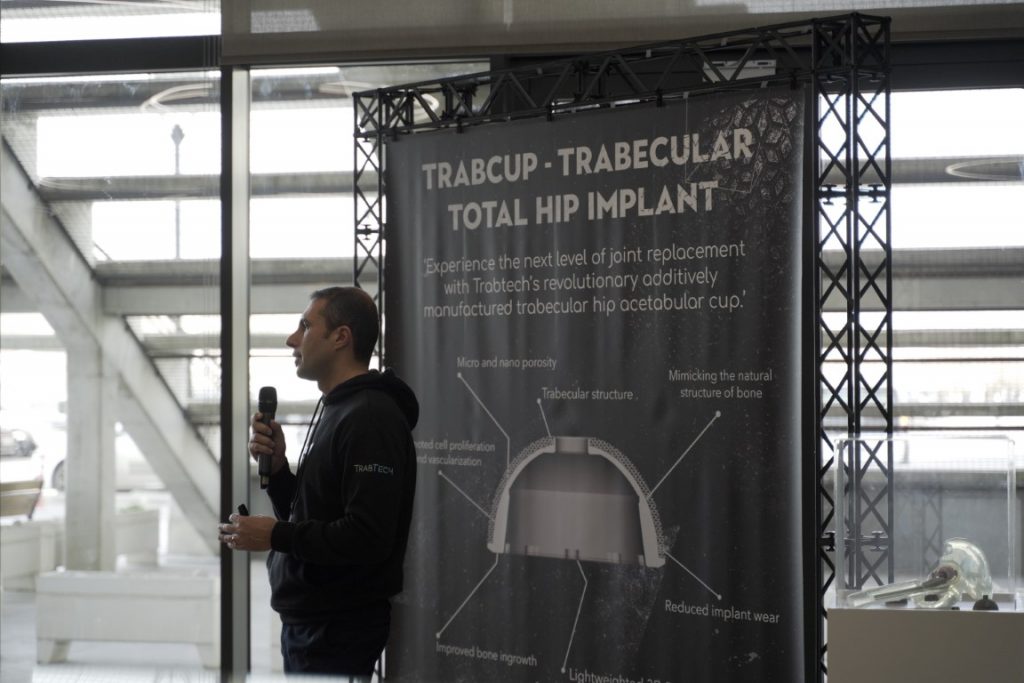

TrabTech, a cutting-edge medical additive manufacturing spin-off of Btech, is thrilled to announce a major new investment and research fund of 1.3 million euros for the development of advanced 3D printed implant applications. With this funding, TrabTech will be able to complete the regulatory process for its innovative new products, relocate its headquarters to Germany to enter the EU market, and prepare for FDA approval, all while commercializing its first mass-produced product, the revolutionary TrabCup hip prosthesis.

Founded by Kuntay Aktaş, Dr. Erol Teberoğlu, and the founders of BTech, TrabTech is pioneering a series of “Trabecular Implants” using additive manufacturing. These implants are one of the few examples that can be serially manufactured with additive manufacturing and can quickly integrate with bone, provide fast healing, and be used in young and old patients thanks to their trabecular surface technology, which resembles the trabecular structure of bone and promotes the growth of bone and tissues. Additionally, the porous structure of the implants maximizes tissue and blood flow, creating a special environment for cells to cling to at the nano level. The titanium material and additive manufacturing used to produce the implants provide high biocompatibility, strength, and low friction coefficient, as well as flexibility and easy stabilization, thereby increasing the lifespan of the implants in the human body and improving the quality of life of elderly or previously inactive patients.

With this new funding, TrabTech will continue its research and development activities, as well as further improve the Trabecular Implant series and create new products in the orthopedic and pediatric fields. The company’s goal is to bring its products to market as soon as possible and make a difference in the lives of patients with its innovative and unique approach.

TrabTech CEO Kuntay Aktaş had this to say about the company’s progress: “When we first started working in this field, the ‘Additive Manufacturing’ technology and medical applications were not well-known. Today, we can see the acceptance of a technology that is set to revolutionize the implant industry. Such transformations can only be achieved through strong collaborations. We bring our developed products to life through collaborations with some of the most prestigious universities and institutions in the world. TrabTech is not an implant or orthopedic company, it’s a new generation technology company that uses methods, tools, ways of working, and multinational company culture that goes beyond its developed products. Our collaborations with important institutions in Switzerland, Germany, Sweden, the United Kingdom, and the United States are particularly exciting for us, as they reflect our vision and competence. Our goal is to be one of the world’s leading technology companies in the field of additive manufacturing.”

TrabTech, which was established in Turkey and is currently in the process of setting up its European office, is also excited to announce a new research project set to begin in 2023. As a leader in the field of “Additive Manufacturing,” also known as 3D printing in the medical field, TrabTech is a member of many research groups in Europe’s most prestigious and important universities and institutions. In recent months, TrabTech, as the project coordinator, received approval from the European Commission for this new project. The goal of the project is to develop implant products using artificial intelligence-supported various design methods and special porous structures through a new process. Stay connected and up-to-date with all of TrabTech’s research and developments by following our social media channels.